Filling Tomorrow's Needs Today

Innovative Single Use Systems for Bio/Pharma R&D to GMP

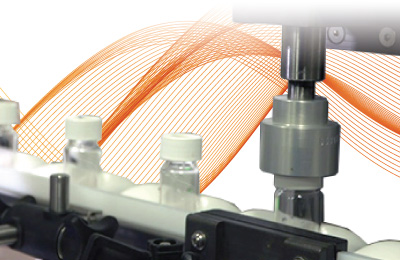

Small Volume Filling

Small Volume Filling

Large Volume Filling

Large Volume Filling

Automated Tray Filling

Automated Tray Filling

Small Volume Filling

Small Volume Filling

Large Volume Filling

Large Volume Filling

Automated Tray Filling

Automated Tray Filling

i-Fill Single Use Kits

i-Fill Single Use Kits

i-Fill Single Use Kits

i-Fill Single Use Kits

Custom Single Use Systems

Custom Single Use Systems

Closure Systems

Closure Systems

Small Volume Filling

Small Volume Filling

The i-FILL® Micro Pump delivers the same repeatable dispense accuracy of the i-FILL® to even smaller fill volumes for delicate product transfer.

Learn MoreLarge Volume Filling

Large Volume Filling

The i-FILL pump is for fill volumes of 100ml to multi liters. The technology is ideally suited for water-like, high-value, sensitive product where product loss is costly and unacceptable.

Learn Moreautomated tray filling

Automated Tray Filling

This affordable fixture is an accessory to the i-FILL Micro that converts your process from manual filling to semi-automatic with ease and simplicity.

Learn Morei-Fill single use kits

i-Fill Single Use Kits

Intellitech offers standard fluid path kit configurations for both the i-FILL Micro and the i-FILL pumps based on target fill volume.

Learn MoreCustom single use systems

Custom Single Use Systems

Whether you need to modify an I-FILL Standard Kit to meet your requirement; or have an entirely custom requirement, Intellitech can meet your needs.

Learn MoreClosure Systems

Closure Systems

The i-CAP® Torque Unit provides automated tightening of container screw tops.

Learn moreAbout Us

With years of proven experience in benchtop precision liquid dispensing and in benchtop closure solutions our products are satisfying our customers through their “Ease of Use” and reliable performance for the Pharmaceutical, Life Sciences and Specialty chemical industries.

We are also an Innovative manufacturer of value-added single-use process components and assemblies, cell transfer bottles and manifolds for the Pharmaceutical, Life Sciences and Specialty chemical industries.

- Innovation

- Precision

- Versatility

- Innovation

- Precision

- Versatility

Explore Our Services

Product Design

- Requirements and Specification

- Feasibility

- Risk Analysis

- Drawings

Prototype

Testing / Validation

Precision Liquid Filling – Validated Accuracy

Request a Quote

Innovative solutions that are custom configured to meet your needs.

Contact us today to build a custom liquid filling machine with tighter fill tolerances to suit you.