i-FILL Micro

Accurate and Repeatable Small Volume Filling,

Qualified for Cell Transfer

i-FILL Micro - Small Volume Filling

The i-FILL® Micro is a hybrid piston/diaphragm pump that delivers repeatable dispense accuracy for small fill volumes up to 15mL per piston stroke. It is also ideal for delicate product transfer.

The i-FILL Micro Offers

- Semi-automated R&D, Lab, or Production Filling

- Fill volumes up to 15mL per stroke

- No tubing spallation

- Multiple dispensing and flow rate profiles that can be stored as recipes

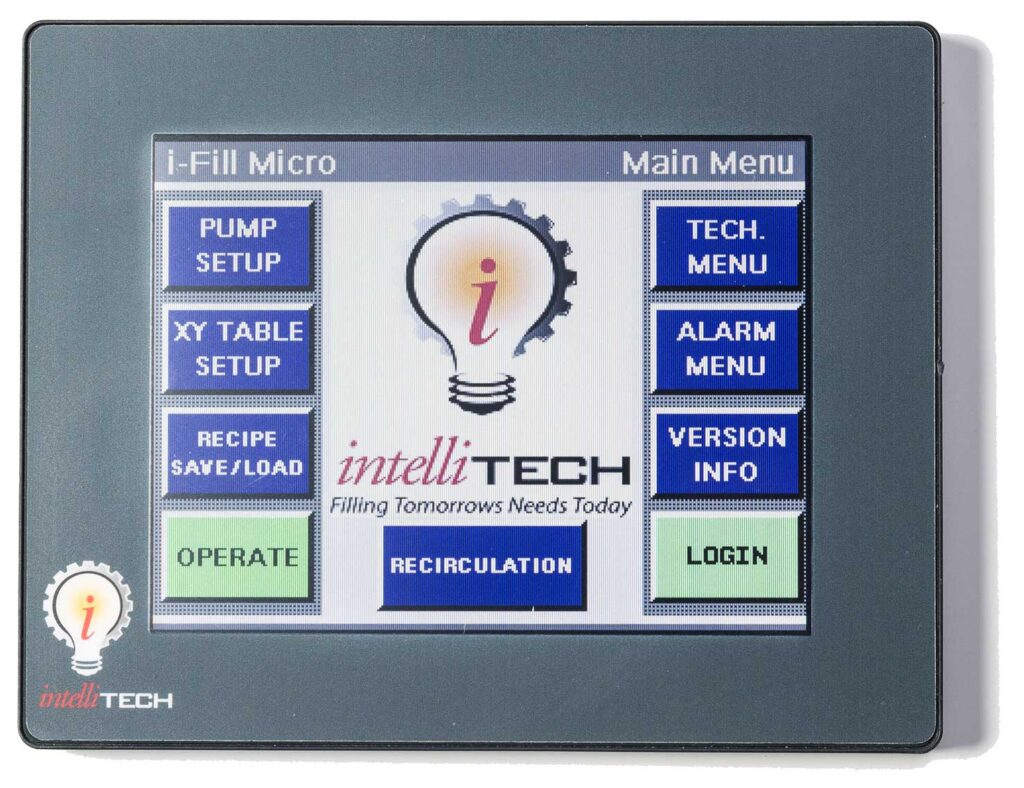

- Ease of operation with its user-friendly interface

- Elimination of repetitive stress injuries from manual pipetting

- Elimination cleaning and sterilization protocols with a single-use pump head

- Self-priming

- No dripping between dispenses

- Ability to pump dry, eliminating Product Waste

Contact Us to Learn More About the i-FILL Micro

A user-friendly interface allows users to easily adjust fill volumes, fill speeds, and flow rates. These settings can be saved into recipes to fit specific unit operations.

Intellitech collaborated with University of South Florida to study the i-FILL pump and a leading peristaltic pump for cell viability.

2 studies have been conducted to examine the application of the i-FILL Micro pumps for transporting live cells. The team conducted Trypan-blue cell viability experiments with sample volume suspensions. In the first study, NIH-3t3 mouse fibroblast cells were used. In the second study, human donor T-cells were used. In both studies, the cells were examined via live-cell imaging. The 2nd study also utilized Presto-blue assays as another method for measuring cell viability.

In both studies, the results showed that the i-FILL Micro is capable for cell culture conditions during development and production. It is now qualified to be a viable alternative to the peristaltic pump.

While the i-FILL pump has performed as a highly accurate dispensing pump, it is proven to be a highly capable cell transfer pump for both upstream and downstream cell culturing and bioprocessing, e.g. product transfer from a mixing vessel to filtration, from filtration to cell harvesting and transfer to either a finishing or a storage vessel.

Interested in learning more? Please provide your contact information to receive an executive summary from one of the cell viability studies.

Intellitech Products

Many of our customers are involved in biologic drug/therapy/vaccine R&D and transitioning to GMP production and we, at Intellitech, believe we can best support those efforts by continuing to focus on manufacturing and improving the i-FILL family of precision liquid dispensing pump technology and single-use systems.

Single Use Assemblies

Single Use Assemblies

Intellitech has unique experience in the design, development and manufacture of many assemblies used in BIO/PHARMA development and production.

Read MoreFluid/Cell Transfer Pump

Fluid/Cell Transfer Pump

The i-Fill® pump is proven effective to transfer live cells with little to no effect on the cells after varying tested periods of time.

Read MorePrecision Filling Pump

Precision Filling Pump

The i-Fill® delivers unmatched, repeatable dispense accuracy over thousands of dispenses for volumes of 100mcL to 100mL.

Read More