Single-use bag assemblies play a crucial role in the development of biologic and pharmaceutical drug products, as well as cell and gene therapies, which has revolutionized the healthcare industry in recent years. According to a report by Grand View Research, the global biopharmaceuticals market size was valued at $337.3 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 7.5% thru to 2028. These complex and sensitive products require a reliable and efficient manufacturing process. According to a survey by BioPlan Associates, over 85% of biopharmaceutical manufacturers use single-use technologies in their production process. These disposable containers are available in 2D and 3D configurations and offer several advantages over traditional, reusable containers, including reduced risk of contamination, scalability, and increased efficiency.

Single-use bag assemblies play a crucial role in the development of biologic and pharmaceutical drug products, as well as cell and gene therapies, which has revolutionized the healthcare industry in recent years. According to a report by Grand View Research, the global biopharmaceuticals market size was valued at $337.3 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 7.5% thru to 2028. These complex and sensitive products require a reliable and efficient manufacturing process. According to a survey by BioPlan Associates, over 85% of biopharmaceutical manufacturers use single-use technologies in their production process. These disposable containers are available in 2D and 3D configurations and offer several advantages over traditional, reusable containers, including reduced risk of contamination, scalability, and increased efficiency.

What are Single-Use Bag Assemblies?

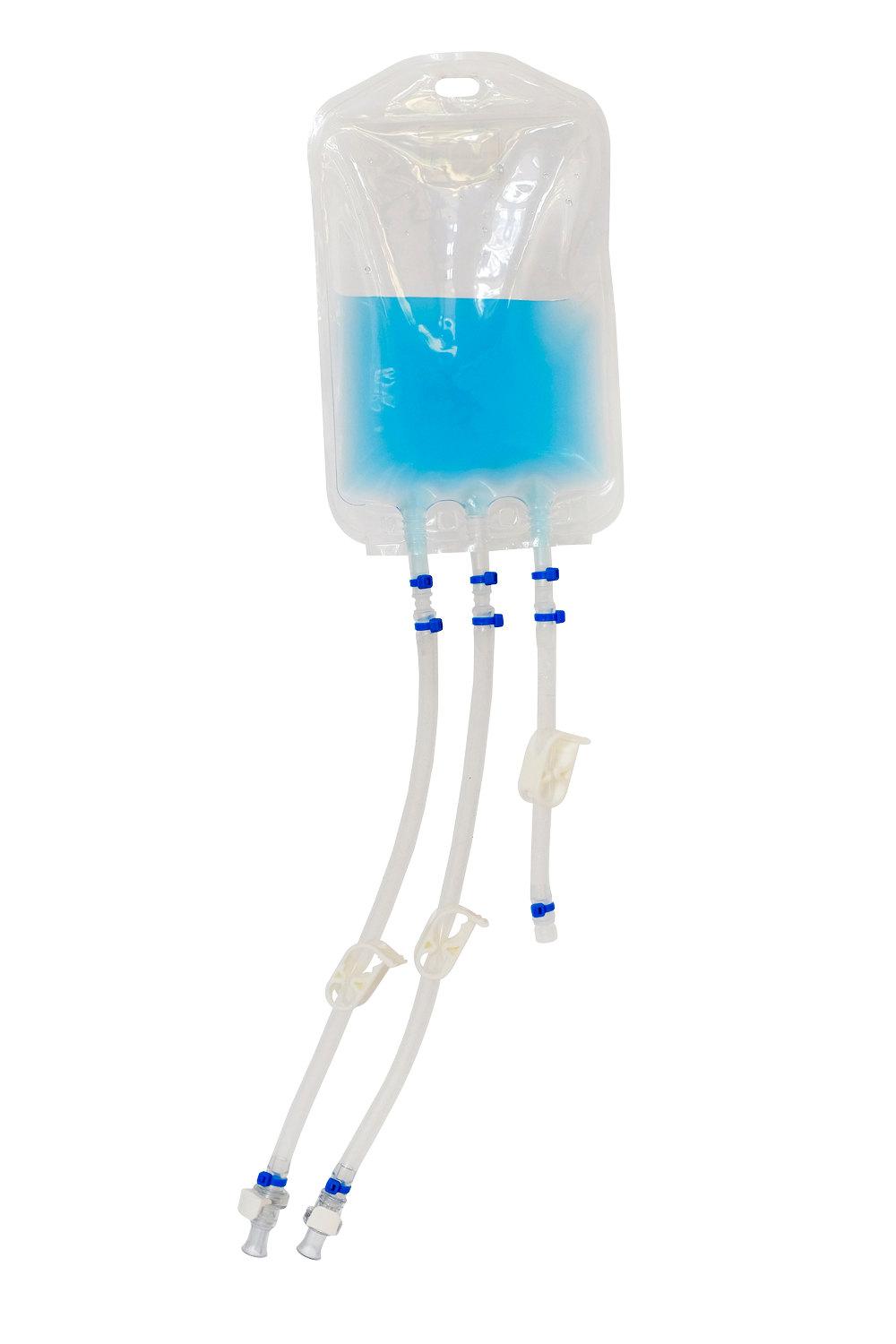

Single-use bag assemblies are a type of disposable container that is used for the storage and transportation of biologic and pharmaceutical drug products, as well as cell and gene therapies. They are available in 2D (flat) and 3D configurations that offer several advantages over traditional, reusable containers.

2D and 3D Configuration Advantages

One of the key advantages of single-use bag assemblies is their ability to reduce the risk of contamination. A study published in the Journal of Pharmaceutical Sciences found that single-use bag assemblies reduced the risk of contamination by over 60% compared to traditional containers. Biologic and pharmaceutical drug products, as well as cell and gene therapies, are often produced using living organisms and are therefore subject to a higher risk of contamination compared to traditional small molecule drugs.

One of the key advantages of single-use bag assemblies is their ability to reduce the risk of contamination. A study published in the Journal of Pharmaceutical Sciences found that single-use bag assemblies reduced the risk of contamination by over 60% compared to traditional containers. Biologic and pharmaceutical drug products, as well as cell and gene therapies, are often produced using living organisms and are therefore subject to a higher risk of contamination compared to traditional small molecule drugs.

In addition, single-use bag assemblies can be pre-validated and used in a consistent manner, which helps to ensure that the storage and transportation processes are performed correctly and consistently. This consistency is critical for maintaining the quality and consistency of the final biologic or pharmaceutical drug product or cell and gene therapy.

The scalability of single-use bag assemblies is also a key advantage. They can be quickly connected to existing storage and transportation systems and can be scaled up or down as needed to meet changing production requirements. These characteristics make single-use bag assemblies well-suited to the development of biologic and pharmaceutical drug products, as well as cell and gene therapies.

Minimize Downtime and Increase Efficiency

Finally, the use of single-use bag assemblies helps to minimize downtime and increase production efficiency. A report by the BioPhorum Operations Group found that over 75% of biopharmaceutical companies reported that single-use bag assemblies reduced downtime and increased production efficiency. This is especially important in the biopharmaceutical industry, where the production of biologic and pharmaceutical drug products, as well as cell and gene therapies, is typically expensive and time-consuming.

Finally, the use of single-use bag assemblies helps to minimize downtime and increase production efficiency. A report by the BioPhorum Operations Group found that over 75% of biopharmaceutical companies reported that single-use bag assemblies reduced downtime and increased production efficiency. This is especially important in the biopharmaceutical industry, where the production of biologic and pharmaceutical drug products, as well as cell and gene therapies, is typically expensive and time-consuming.

Intellitech can provide 2D and 3D bags in both standard and custom designs with multiple port configurations, both for media/buffer storage, transfer and mixing.

In Conclusion

In conclusion, the use of 2D and 3D single-use bag assemblies is critical to the development of biologic and pharmaceutical drug products, as well as cell and gene therapies. They offer several key advantages, including reduced risk of contamination, consistency in storage and transportation processes, scalability, and increased efficiency, making them an indispensable tool in the production of these complex and sensitive products.

Intellitech™ has broad experience providing a full spectrum offering of single use systems for various applications from development through full scale GMP production. We support customers with design, development, manufacture, assembly, packaging, post processing (gamma irradiation) as well as validation studies of single-use systems for package integrity, seal strength, shelf life, bio-burden, sterility and dose audits.

Call 727-202-6419 or email sales@intellitech-inc.com to discuss your project with one of the leading companies innovating single-use systems for the life science industry.